From Busworld to the Factory Floor: Why It Matters for Operators

- November 7, 2025

- Blog

- Posted by Isaac Cornell

- Comments Off on From Busworld to the Factory Floor: Why It Matters for Operators

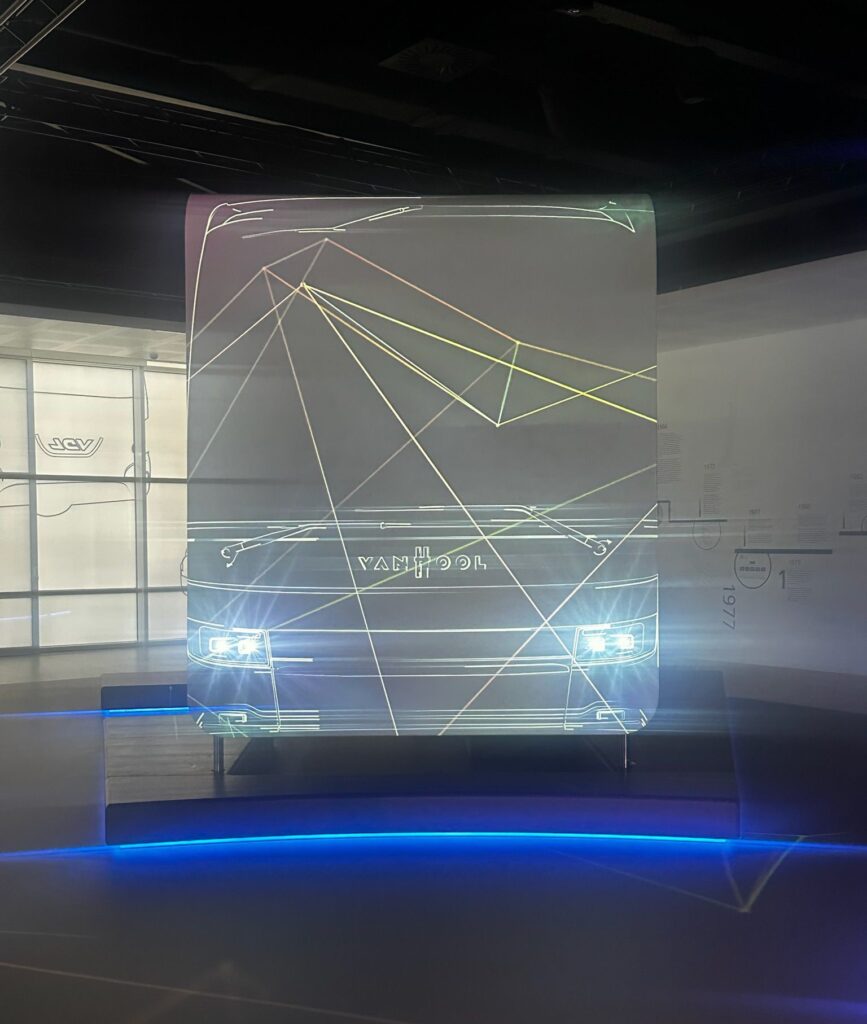

I traveled to Brussels recently to represent ABC Companies at Busworld 2025, one of the largest global events for the bus and coach industry. I also visited VDL Groep headquarters and our manufacturing partner, VDL Van Hool, in North Macedonia.

The goal was simple: to observe, listen, and learn what is next for our industry, and to bring back insights that can help operators prepare for what is ahead. The trip reminded me that innovation is not just about new technology. It is about small improvements in process, design, and craftsmanship that make vehicles easier to run, service, and depend on.

What Stood Out at Busworld 2025

Walking through the halls at Busworld offered a front-row view of how manufacturers are thinking about the next generation of vehicles. I focused on areas that connect directly to how operators run their fleets, including maintenance, driver comfort, and passenger experience:

1. Designing for Serviceability

Many of the most impressive coaches were not defined by what was new, but by what was improved. Cleaner wiring layouts, better diagnostic access, and simplified components are helping reduce maintenance time. For operators, that means less time off the road and more predictability in the shop.

2. Driver Experience as a Performance Factor

I paid close attention to cockpit layouts and sightlines. Simple changes, such as improved switch placement and clearer visibility, can make long driving days less tiring and safer. Driver comfort translates to better focus and fewer on-road incidents, which are key to consistent performance.

3. Passenger Comfort and Operational Flow

Lighting, storage, and boarding design were a major focus this year. Smooth passenger flow, adequate luggage space, and intuitive lighting do more than improve comfort. They make trips more efficient and reduce wear on high-touch areas. It is a reminder that passenger experience is an operational factor, not just an aesthetic one.

4. Practical Efficiency

Instead of futuristic concepts, the focus this year was on practicality. Lightweight materials, modular systems, and components built for longevity were front and center. Manufacturers are prioritizing solutions that fit real-world duty cycles and make daily operations easier.

Inside VDL Groep: Innovation Built on Family Legacy

Visiting VDL Groep headquarters was impressive. The scale of the company and the variety of industries they support caught my attention. They are involved in everything from automotive technology to defense and microelectronics.

Their innovation center was one of the highlights. It told the story of the VDL family, their growth, and their approach to innovation. The presentation showed how they combine advanced technology with a hands-on, family-driven culture. Seeing the family members themselves explain their story made it personal and memorable.

What I appreciated most was how practical their innovation is. Every idea is tied to reliability, safety, and ease of use. They are focused on improving systems that make vehicles simpler to operate and maintain. That mindset aligns closely with what we value at ABC, solving real challenges for operators and customers.

At Van Hool in North Macedonia: Organization and Craftsmanship

Visiting the Van Hool factory in North Macedonia was another highlight of my trip. The manufacturing plant is modern, well-organized, and built around a consistent production rhythm. Each station follows a defined process, and every team member’s role is clearly defined. Parts are delivered to each station in the exact quantities needed, which keeps production steady and predictable.

From frame welding to final assembly, each step includes documented checks. Frames are treated with a protective coating before the panels are installed to prevent corrosion. I watched as teams worked through sealing, alignment, and painting preparation with real precision. The result is a product that stays quiet, clean, and solid even after years on the road. That kind of consistency does not happen by chance. It comes from people who take pride in their work and understand how their craftsmanship impacts operators around the world.

There is also a structured area dedicated to quality control and component testing. It is where parts are verified and reviewed before being approved for use. Seeing that level of discipline reinforced how serious they are about reliability.

One of my favorite moments was talking with my grandfather, Dane, about his earlier visit to the same factory. He described how much it has grown, both in size and workforce. Hearing that perspective and then seeing the progress firsthand was a powerful reminder of how far the partnership and operation have come.

Why These Visits Matter

Trips like this help bridge the gap between what manufacturers design and what operators experience. They allow us to see how decisions made in Europe connect to how fleets perform in North America.

For operators, this perspective matters because it leads to better communication and faster problem-solving. When we understand how vehicles are built, we can help translate that knowledge into clearer maintenance guidance, improved training, and more predictable performance outcomes.

What Operators Can Take Away

While every fleet’s needs are different, a few lessons stood out during this trip that apply across the industry:

- Simplify where possible. The best designs reduce steps instead of adding them.

- Evaluate technology. If a vehicle uses mirrorless or camera systems, evaluate how the displays perform in all conditions and how the driver interacts with them.

- Prioritize the driver’s environment. Comfort and visibility directly affect performance.

- Value consistency over novelty. A process that delivers the same result, coach after coach, is more valuable than an untested idea.

- Ask about quality control. Find out how each manufacturer tracks and resolves component issues.

- Check the build process. A consistent and documented assembly process often translates to more reliable vehicles.

- Share field feedback. The best improvements come from real operators, drivers, technicians, and passengers’ input. Make sure your feedback is being shared with your manufacturer and dealer contacts.

These lessons may seem simple, but they are what separate reliable equipment from complicated equipment.

Partnership and Purpose

This trip reminded me that progress in our industry comes from partnership and shared purpose. At every stop, from Busworld to VDL Groep and the Van Hool facility in North Macedonia, I saw people focused on the same goal: building better vehicles for operators. I left feeling appreciative of our customers, our partners, and the teams who bring these vehicles to life. When manufacturers, distributors, and operators stay connected and open to feedback, good ideas become reliable equipment and relationships that strengthen the entire industry.